Continuous fiber reinforced thermoplastic composite is a new product developed by Shanghai Leadgo-tech Co., Ltd. in 2018. The project adopts advanced resin melt impregnation process and yarn spreading technology to prepare prepreg with uniform thickness, smooth appearance and high performance. Continuous fiber reinforced thermoplastic composites with high strength, high toughness and high stiffness are widely used in aerospace, train, automobile, container, construction, pipeline, sports and leisure fields. The main product forms include: unidirectional prepreg tape, composite laminate, sandwich board, etc.

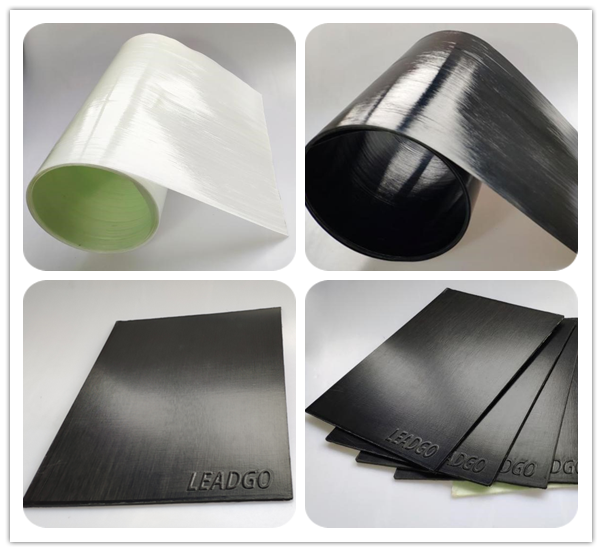

1. Unidirectional prepreg tape:

The unidirectional prepreg tapes are made of polypropylene (PP), polyethylene (PE), nylon (PA), polyphenylene sulfide (PPS) and other thermoplastic resins as matrixes, continuous glass fiber and carbon fiber as reinforcement materials, which are manufactured by melt impregnation process. They can be used as composite pipe reinforcement, winding gas cylinder, etc.

Product features:

Ø The resin matrix and reinforced fiber can be selected according to the needs;

Ø Natural color and black are conventional product colors, other colors can be customized;

Ø The material has light weight, high specific strength, high specific modulus and excellent mechanical properties;

Ø Dry storage, long storage life;

Ø Recycling, environmental protection, sustainable development;

Ø Materials and products have no harmful volatilization;

Ø Good corrosion resistance and moisture resistance;

Ø The product design is flexible and the product performance is controllable;

Ø Advanced technology, automatic production.Ø

|

Table 1 Technical datasheet of unidirectional prepreg tapes |

|||||||

|

Property |

Unit |

LTP21-CF-45%-330GSM |

LTP21-CF-50%-300GSM |

LTP21-GF-60%-485GSM |

LTP21-GF-65%-450GSM |

LTP21-GF-70%-415GSM |

Test Method |

|

Density |

g/cm3 |

1.11 |

1.19 |

1.49 |

1.53 |

1.64 |

GB/T1033

|

|

Fiber content |

%wt |

45 |

50 |

60 |

65 |

70 |

GB/T9345.1

|

|

Thickness |

mm |

0.29 |

0.26 |

0.32 |

0.29 |

0.26 |

GB/T 6672

|

|

Weight |

g/m2 |

330 |

300 |

485 |

450 |

415 |

GB/T 20220

|

|

0 ° tensile strength of unidirectional tape |

MPa |

≥750 |

≥900 |

≥700 |

≥750 |

≥800 |

ASTMD309 |

The above data are the average values determined by the laboratory, and are only used for reference, not as product standards.

2. Composite laminate:

Composite laminate is made of unidirectional tapes with orthogonal ply. The unidirectional tapes can be laid in different order with different angles (0°、±45°、90°). Under the heating and pressure of the compound machine, the fibers continuities are maintained, and at the same time, the laminate is reinforced in each direction according to the design, which has better mechanical properties and lighter weight. It can be used to replace steel laminate, glass fiber reinforced plastic and other materials, as well as in various boxes and tanks.

In addition, the thickness, gram weight and strength of the composite laminate can be customized according to customer requirements, and it can be bonded with anti ultraviolet and anti-aging films, as well as non-woven fabrics and decorative films.

Fig. 1 unidirectional prepreg tapes and composite laminates

|

Table 2 Technical data sheet of composite laminates |

|||||||

|

Property |

Unit |

LTP21-CF-45%-330GSM |

LTP21-CF-50%-300GSM |

LTP21-GF-60%-485GSM |

LTP21-GF-65%-450GSM |

LTP21-GF-70%-415GSM |

Test Method |

|

0 ° tensile strength of unidirectional tape |

MPa |

≥400 |

≥450 |

≥300 |

≥320 |

≥340 |

ASTMD309 |

|

0 ° tensile strength of composite laminate |

MPa |

≥400 |

≥450 |

≥300 |

≥320 |

≥340 |

ASTMD309 |

|

90 ° tensile strength of composite laminate |

MPa |

≥120 |

≥140 |

≥300 |

≥320 |

≥340 |

ASTMD790 |

|

0° flexural strength of composite laminate |

GPa |

≥28 |

≥36 |

≥15.5 |

≥18.5 |

≥20 |

ASTMD790 |

|

0 ° flexural modulus of composite laminate |

MPa |

≥85 |

≥110 |

≥230 |

≥250 |

≥275 |

ASTM D790 |

|

90 ° flexural strength of composite laminate |

GPa |

≥19 |

≥22 |

≥8 |

≥10 |

≥11 |

ASTM D790 |

The composite laminates are prepared by laying prepregs at 0 °/ 90 ° angles. The above data are the average values determined by the laboratory, and are only used for reference, not as product standards.

3. Application

Ø Automobile: seat frame, bottom guard board, door base laminate, bumper beam, spare tire luggage compartment, etc;

Ø Aviation: aircraft seat frame, bracket, engine nacelle, radome and other aircraft parts;

Ø Sports and entertainment: paddle, sledge;

Ø High pressure oil and gas pipelines;

Ø Sandwich laminate: truck cargo box, floor spreader, mobile plank house, container, refrigerator, building temlaminate.

Fig. 2 Application fields of continuous fiber reinforced thermoplastic composites